In the area of microfluidic technology, a groundbreaking innovation has emerged, promising to revolutionize the microdroplet era. Spearheaded by Associate Professor Masumi Yamada and his team from Chiba University’s Department of Applied Chemistry and Biotechnology, this novel machine introduces porous inverse colloidal crystal (ICC) systems, unlocking a realm of opportunities within the efficiency and versatility of microfluidic gadgets.

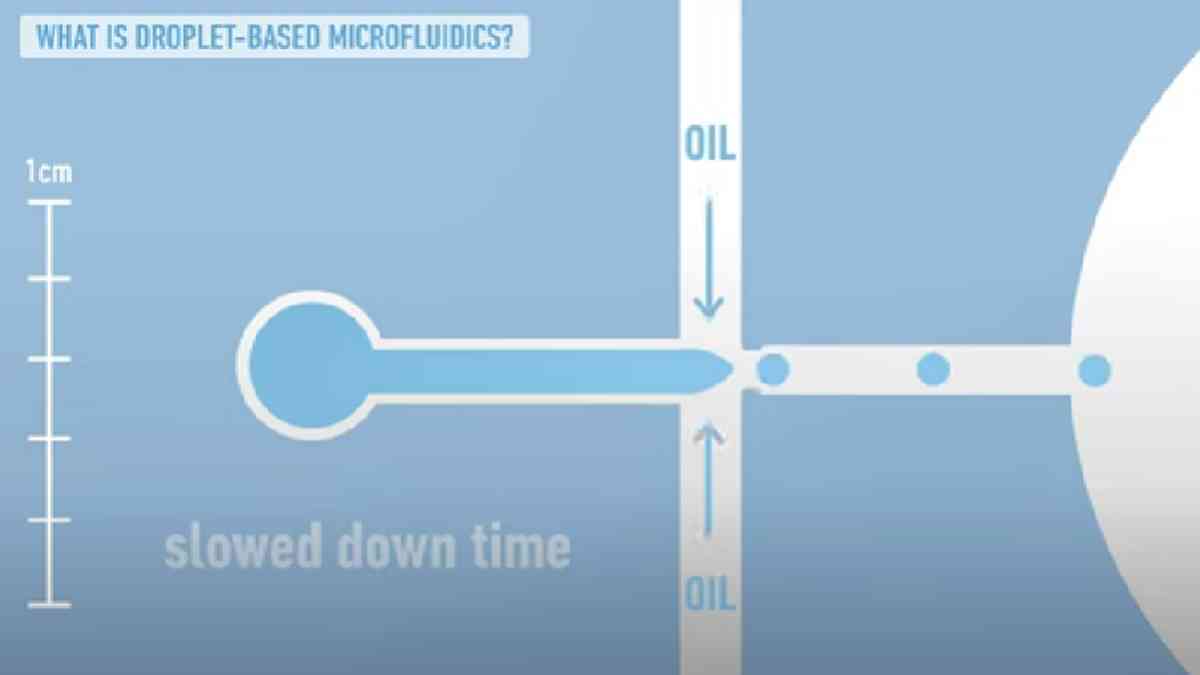

The Mechanism Behind the Innovation: At the heart of this revolutionary study integrated spongy ICC structures, ingeniously integrated inside flat microfluidic channels. These structures, akin to miniature nozzles, facilitate the speedy formation of droplets at an extraordinary tempo. Moreover, the combination of ICC systems elevates the benefit of operation, promising a continuing revel in the microdroplet era.

The importance of this innovation transcends mere pace. With improved droplet formation abilities, this machine opens doors to a myriad of applications across numerous industries. From medicine to cosmetics and from specialized inks to semiconductor production, the capability for transformative impact is gigantic.

Pore Power: High-Speed Droplet Production in THE Microfluidic Devices

Over the past two decades, microfluidic gadgets have turned out to be fundamental gear in diverse domains, ranging from chemical reactions to biomolecular evaluation. However, conventional strategies for droplet technology frequently lag in efficiency, constraining production rates.

Introducing the ICC Advantage

In the latest look featured in the magazine Lab on a Chip, Dr. Yamada and his crew unveiled a paradigm-moving technique. By harnessing the porous nature of ICC systems, the droplet era achieves unprecedented efficiency, outperforming conventional techniques by leaps and bounds.

Notably, the dimensions and houses of the produced droplets may be finely tuned, offering exceptional manipulation and precision. Moreover, the device’s versatility extends to the introduction of micrometer-sized particles, catering to a spectrum of applications beyond droplet formation.

Charting the Future of Microfluidic Technology

Dr. Yamada and his collaborators envision a destiny where this era catalyzes breakthroughs in numerous medical realms. From drug improvement to regenerative medicinal drugs and from immunotherapy to diagnostics, the ability for transformative effects on human fitness is enormous.

Yet, the effect of this innovation transcends the confines of the medical field. Its applications span numerous sectors, including the food, cosmetics, and semiconductor industries, ushering in a brand-new generation of efficiency and innovation.

Unveiling the Potential of ICC Structures

An inverse colloidal crystal (ICC) represents a porous material crafted through a meticulous process of arranging and getting rid of microscopic spheres. The resulting interconnected voids provide a blank canvas for numerous applications driven by their unique homes.

Characterized by their spongy nature, including spongy ICC structures, they redefine the realm of possibility. From more advantageous drug delivery to superior filtration and tissue engineering, the programs are as diverse as they are impactful.

Current Research Trajectories

Ongoing research endeavors cognizance of refining fabrication strategies, exploring novel materials, and unraveling the organic compatibility of spongy ICCs. These efforts pave the way for further advancements, promising to unencumber new frontiers in microfluidic technology.

The unveiling of the modern microfluidic machine marks a pivotal moment in medical innovation. With spongy ICC structures at its center, this system heralds a future in which performance, precision, and versatility converge to redefine the limits of opportunity. As we traverse this course of discovery, guided by the ingenuity of researchers like Dr. Yamada, we embark on a journey in the direction of a brighter, more progressive destiny.

Putting porous inverse colloidal crystal (ICC) systems inside microfluidic channels has changed the way droplets are made and could make many industries and uses much more efficient and flexible. Led by Dr. Masumi Yamada, this groundbreaking innovation holds the capacity to reshape the panorama of microfluidic generation, propelling us toward a future of superior performance and innovation.

+ There are no comments

Add yours